Products

Applications

How to measure Electrical Conductivity of Aluminium alloys

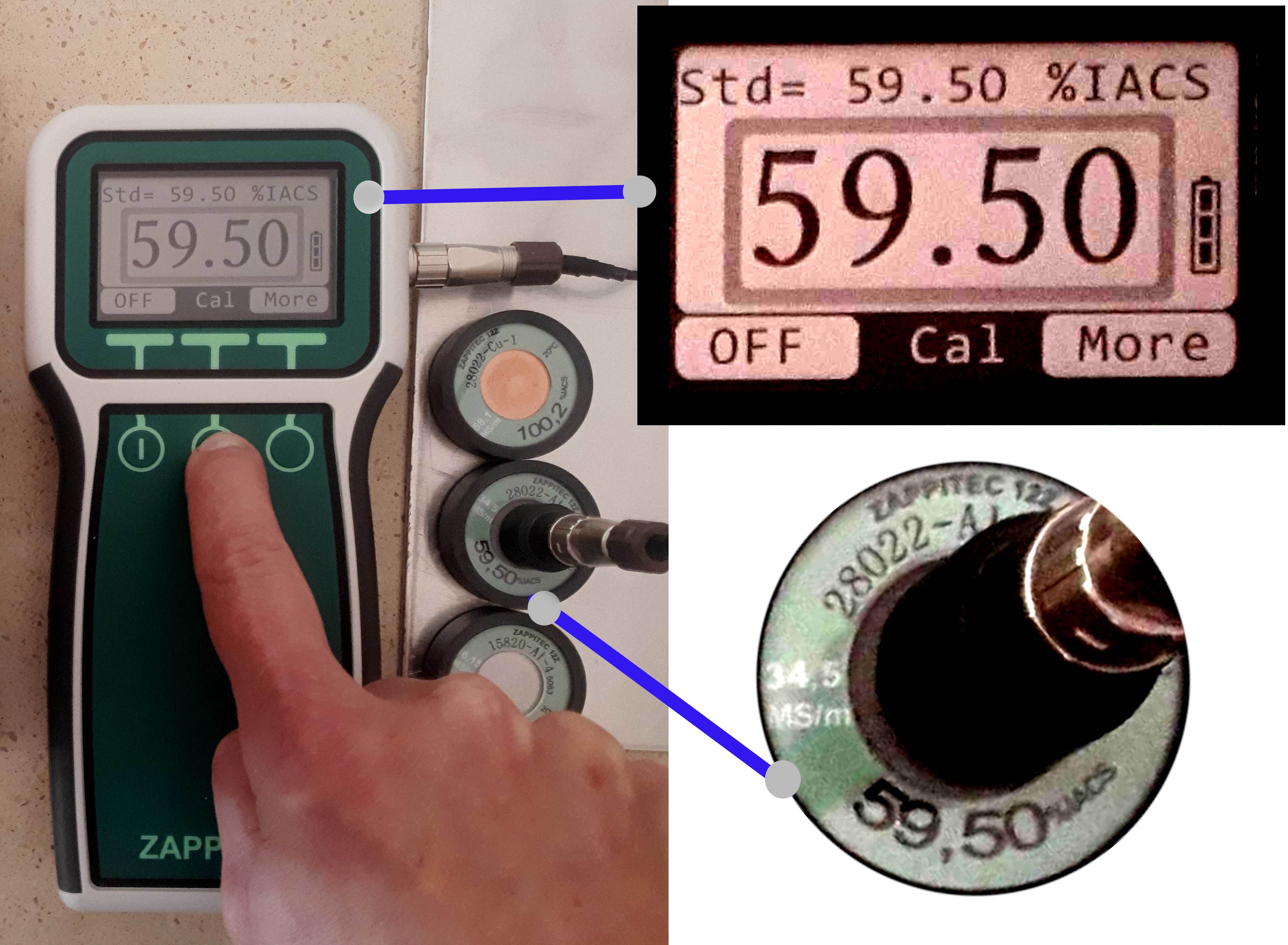

Zappitec's model 12Z allows quick and precise measurement. Here is the procedure:

1. Temperature Equalization

Place your standards in contact with the part you want to measure to allow their temperature to enter equilibrium. This takes a few minutes but it only needs to be done once. If the parts to measure are small, place everything on top of a thick copper or aluminium plate, just to make sure the temperature will be the same. The bottom part of Zappitec Conductivity Standards is exposed to allow for quick temperature equalization.2. Turn on the instrument

Turn on the instrument by pressing the left button.

3. Calibrate the instrument on the apropriate standard

Select the standard which has a conductivity closest to the material to be measured.

Example: if measuring high conductivity aluminium use the standard with ~59 %IACS.

Place the probe on the standard and press the center button. A message will appear on the display indicating that the standard was recognized and the unit is now calibrated.

4. Electrical Conductivity measurement on Aluminium parts